Дата публикации:2022-05-20

Дата публикации:2022-05-20

Источник:

Источник:

Вид Номер:2891

Вид Номер:2891

Application Area:Iron & Steel Industry

Process:Iron Making

Measuring Components:O2+CO

Installation Position:Hot Blast Stove

Feature:Continuously monitoring the concentration of O2 and CO in this process.

Application Scenario:

Iron and steel-making plants adopt combustion gases and inert gases as fuel or protection gases in the iron-making process. At the same time, the iron-making process will generate a variety of process gases, such as CO and O2. Thus, early detection and warning of the concentration of these gases play an essential role in production optimization, safety, energy recovery, environmental protection and energy-saving.

FPI Solution:

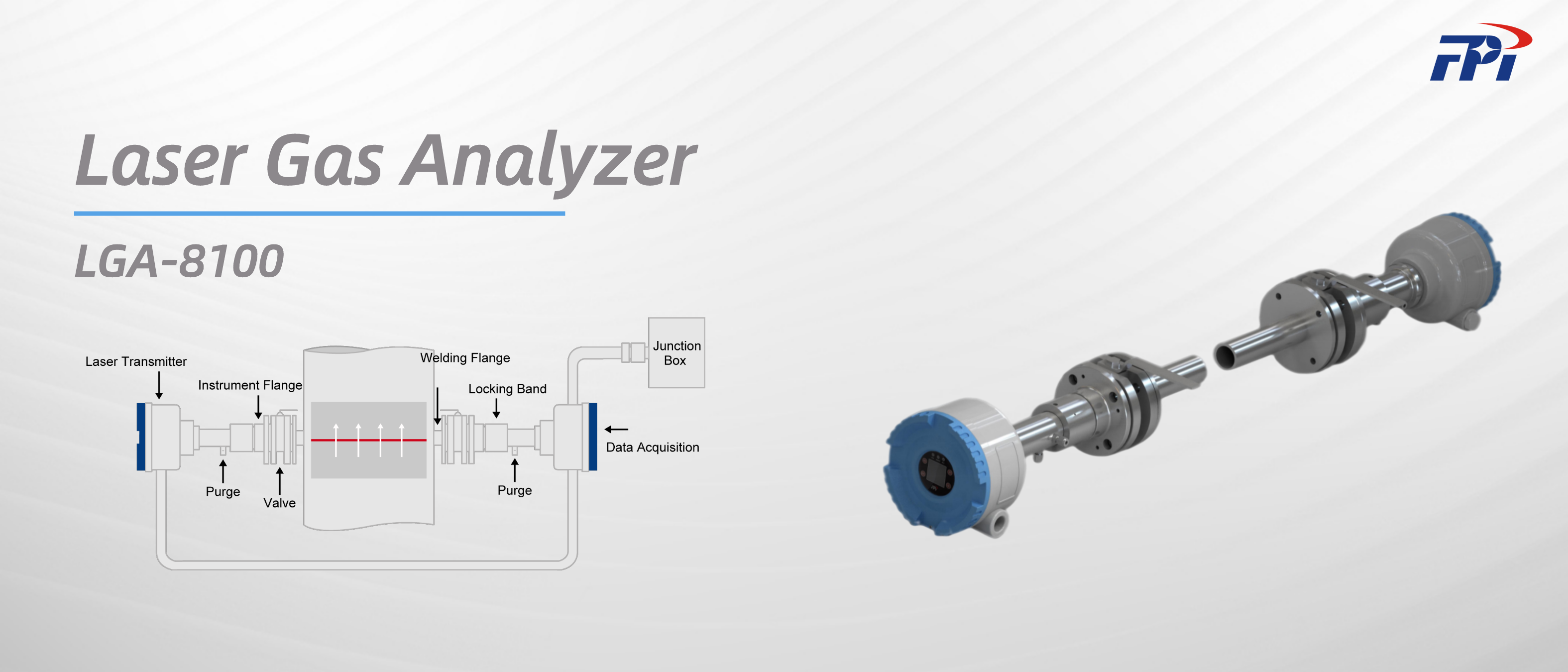

In the above scenario, FPI's LGA-8100 in-situ type laser gas analyzer can continuously monitor and early warn the process gases such as CO and O2, which generate in a hot blast stove. That was made possible by FPI's creative application of TDLAS technology to gas analyzers in 2002. After 20 years of practice and continuous research, FPI launched the LGA-8100 laser gas analyzer.

The LGA-8100 analyzer has an integrated explosion-proof structure, its advantages include portability and high reliability, all in accordance with Ex d IIC T6 standards. It is designed with "functional safety," thereby improving system failure diagnosis capability. The LGA-8100 is widely used in the petrochemical, chemical, metallurgical, and other industries and is particularly well suited to applications that require high product reliability, stability, and safety.

Features and Benefits:

With a low measurement drift and a high level of reliability.

With a high detection sensitivity and a high resistance to interference.

Onsite isolation design eliminates the requirement for positive pressure gas sources.

Enables real-time remote locking and range checking, enhancing the instrument's stability.

Any interest in this product, please feel free to visit FPI’s official online store: online.fpi-inc.com/